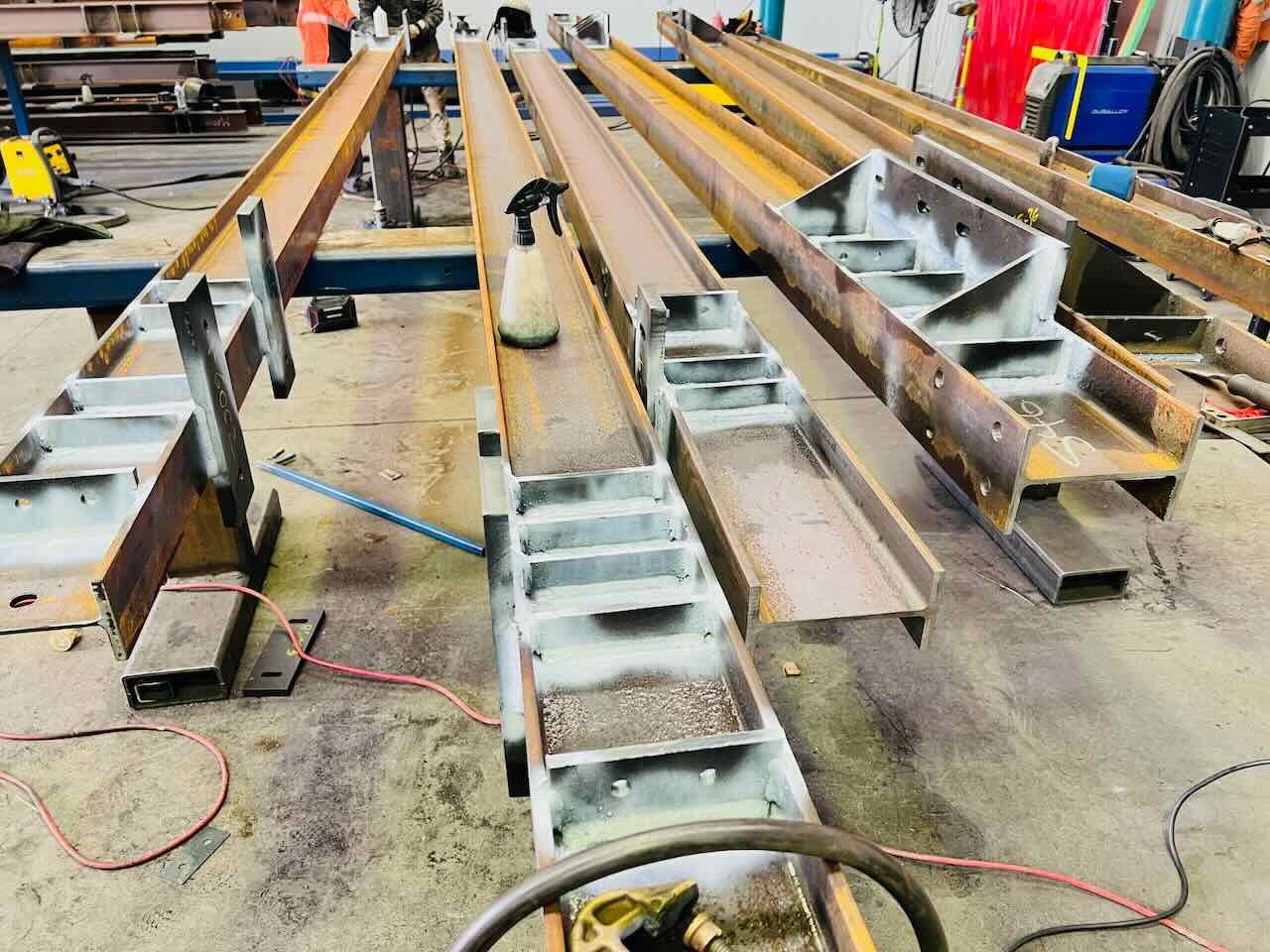

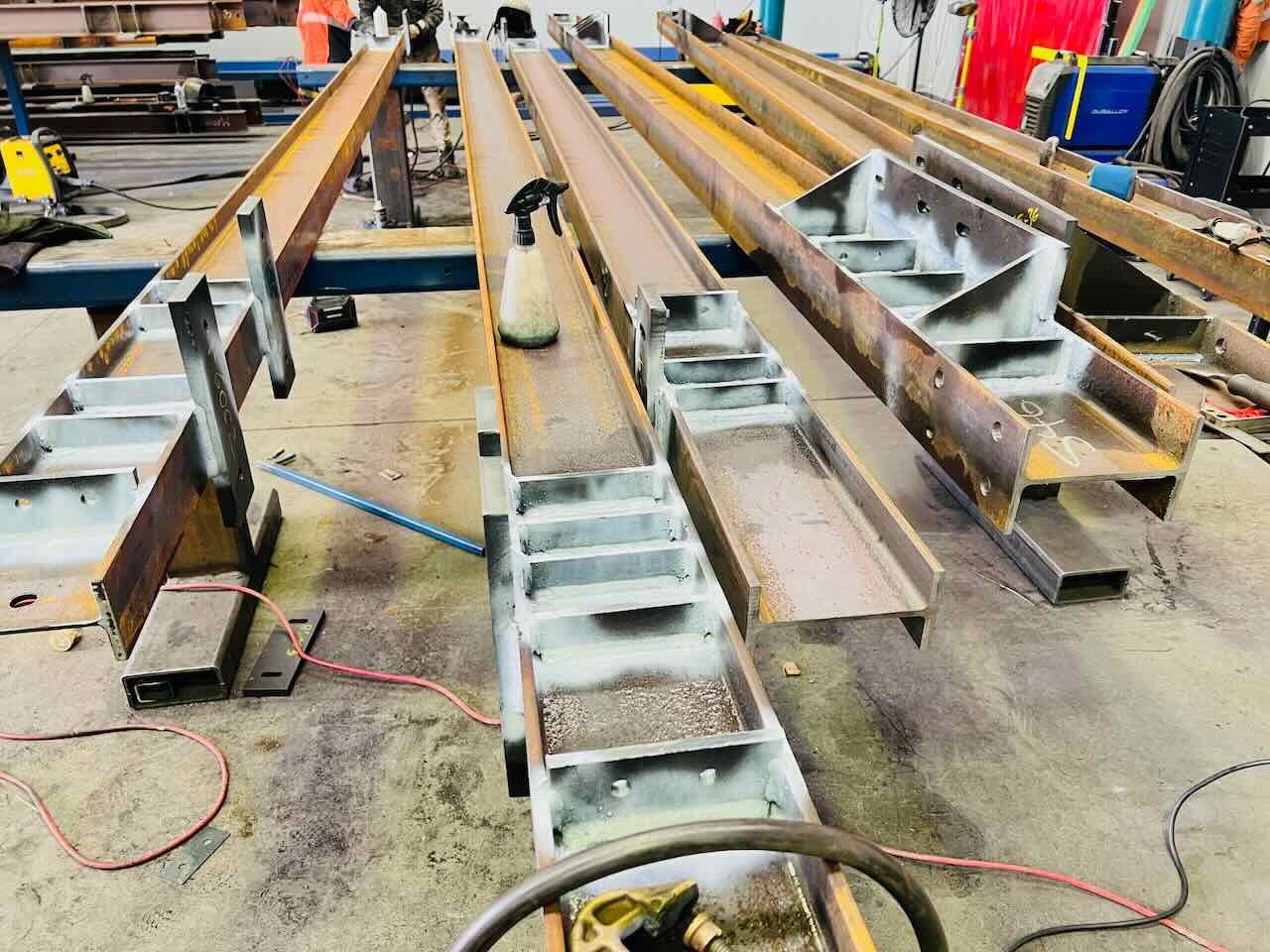

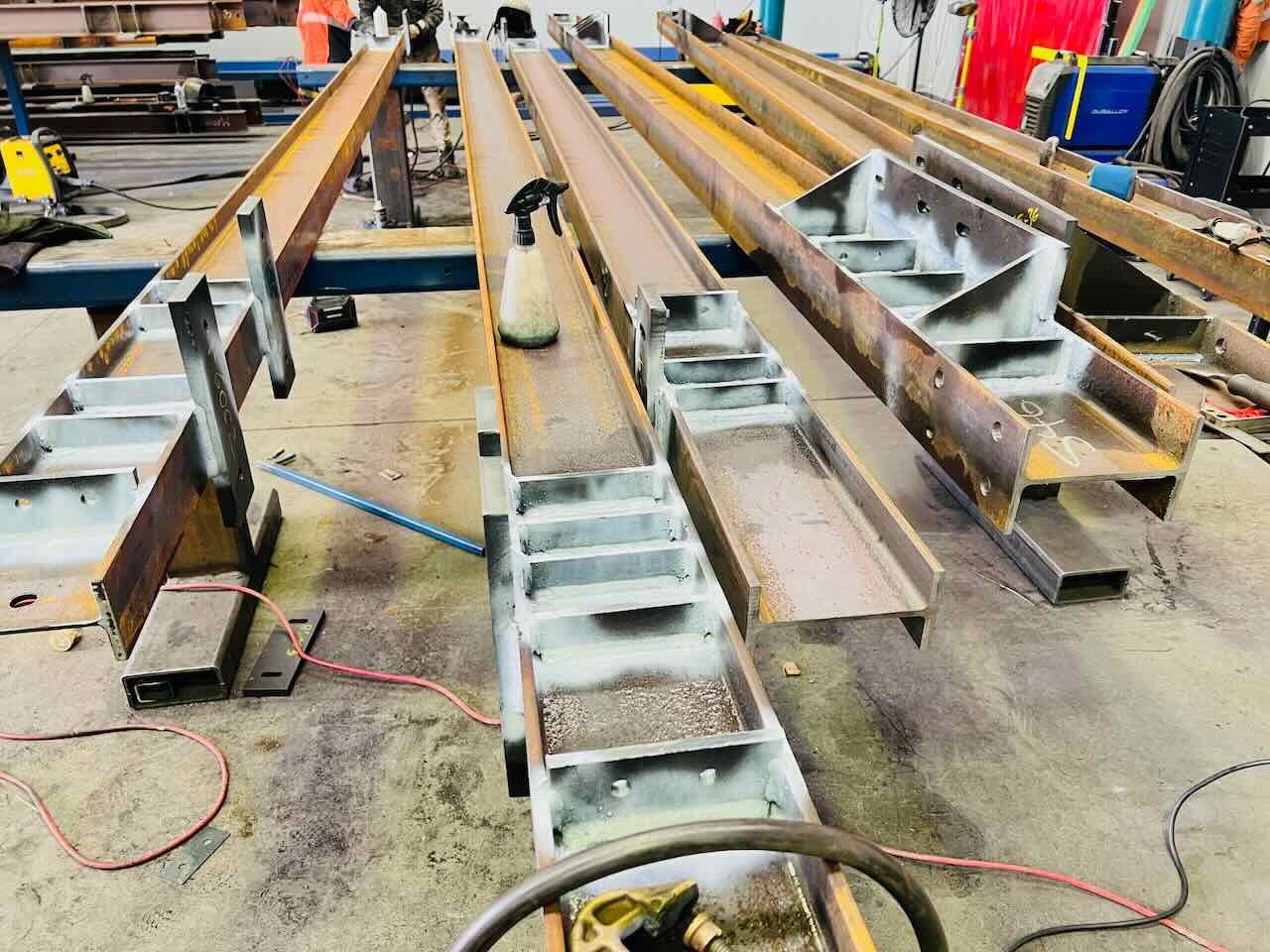

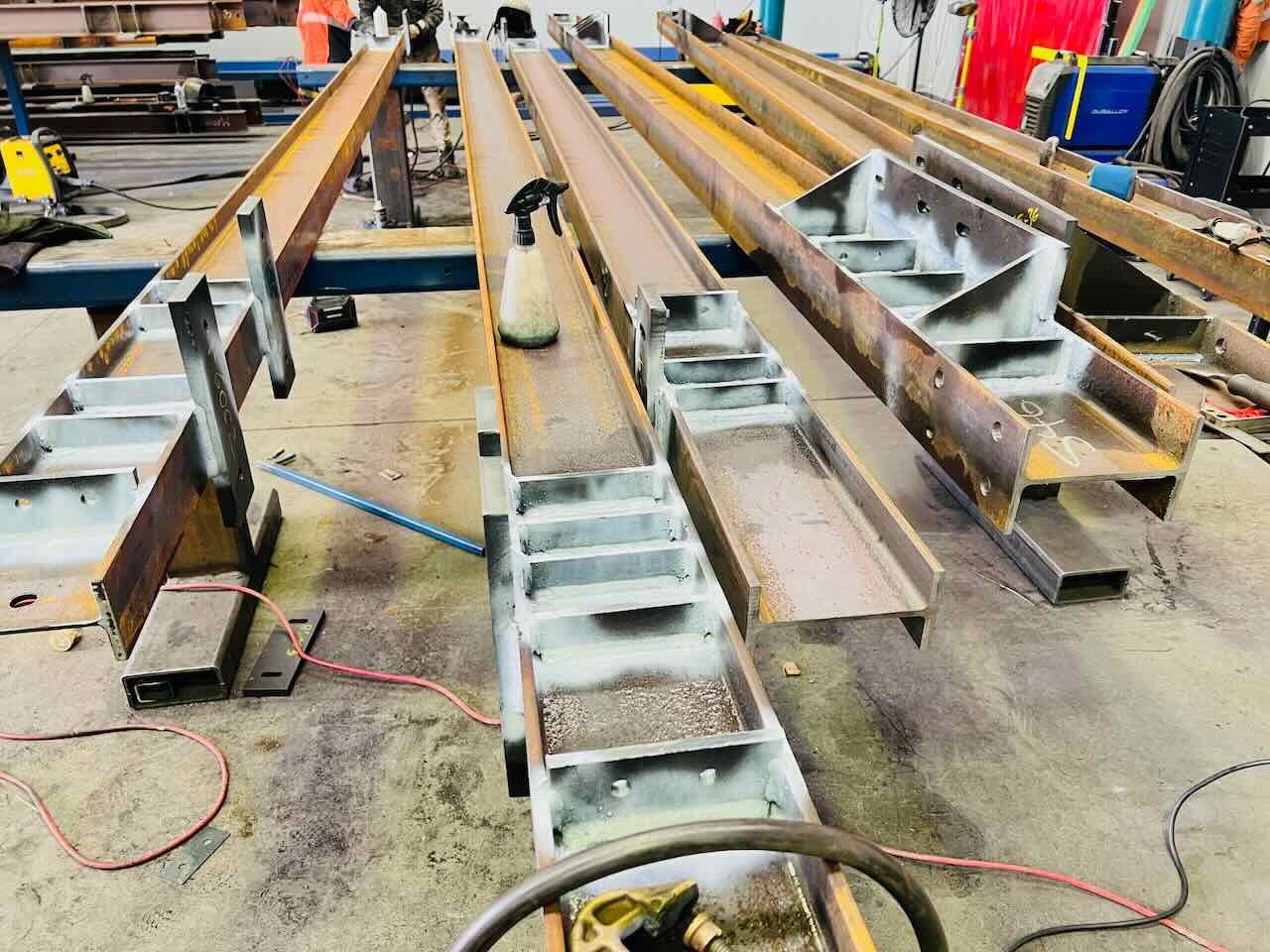

Structural Steel Fabrication

Project Gallery

Our Fabrication workshop is fully equipped with Overhead Cranes and offers full range of manufacturing capability in-house and through our network of reliable suppliers including beamline operations, CNC Laser/Plasma/Oxy profile cutting, Pressing, Rolling, Machining, Bandsaws /Guillotines /Punch & Shear operations, Sub-Arc, MIG, TIG, Stick Welding. First Stage of Fabrication is to note Construction Category, Traceability Requirements, NDT Requirements, Weld types and client specific requirements for each project. Detailed ITPs and Project Management Plans are established and using advanced IT support, all our processes are streamlined throughout the fabrication stages. Weld Maps and QA documentation for Each Assembly and parts are maintained continuoulsy. We have fully developed Welding Procedures and Welder Qualifications Registers (WPS / WPQR) to ensure each Weld is carried out as per specifications. Our QA Inspector and Project Engineer ensures that all Fabrication drawings are detailed properly and any missing information or RFIs are addressed on time. Material Certificates with Heat Signatures are received for each project and recorded for Manufacturing Data Report (MDR). We use third part NDT Inspectors to carry out We employ a highly skilled team of metal fabricators, boilermakers and QA Inspectors to ensure that we deliver the results you expect.

Precise Way is committed to operate with highest levels of Quality Control, Environment and sustainability management and Health and Safety. All our business policies and procedures are aligned with integrated management systems. We are working towards achieving following accreditations ISO 9001: Quality Management System ISO 14001: Environment Management System ISO 45001: OH&S Management System

We have many years of experience in building & construction, so rest assured, if it can be done, we can do it.